The smart Trick of American Plastics That Nobody is Discussing

Wiki Article

American Plastics - An Overview

Table of ContentsAll About American PlasticsAmerican Plastics Fundamentals ExplainedFacts About American Plastics UncoveredMore About American PlasticsAn Unbiased View of American Plastics

Larger tasks may need pipelines with higher sizes to successfully disperse liquids over long ranges. Variables such as surface difficulty, the potential for environmental stress, and the setup setting need to influence the pipeline size to guarantee an effective, lasting application.

Involve with specialist advice to verify your option and adapt as required for ideal outcomes. Equipped with this understanding and the actionable steps outlined, you are well-appointed to make informed choices when picking HDPE pipe dimensions for your projects. Your attention to information in this option process will certainly go a long means in ensuring the efficiency, safety, and cost-effectiveness of your piping systems.

Some Known Questions About American Plastics.

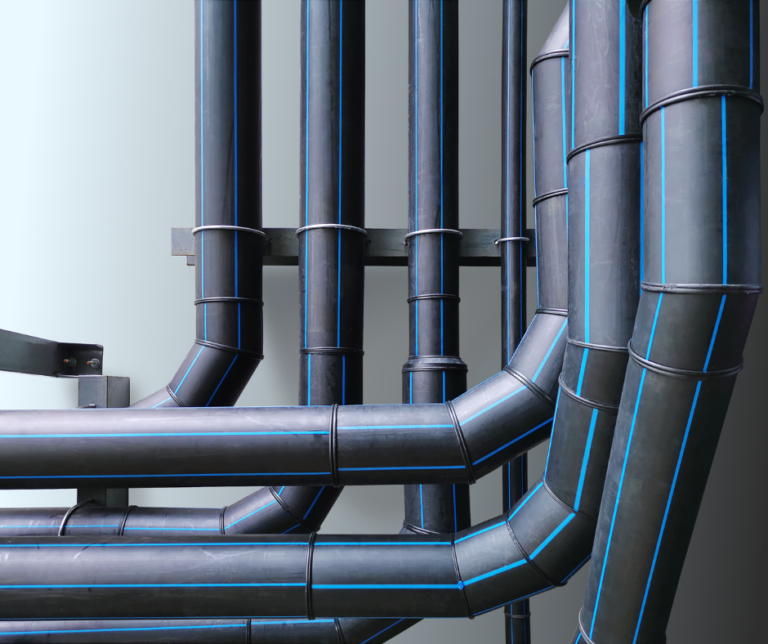

Since HDPE is lightweight and chemically inert, it can deal with fluid and gas transport with very little maintenance. HDPE pipelines are widely embraced throughout a variety of sectors as a result of their adaptability and stamina. One of the most typical usages for HDPE pipe remains in water supply systems. HDPE's rust resistance makes it excellent for both drinkable and non-potable water circulation, whether in community networks or exclusive systems.: HDPE pipelines are signed up with via heat fusion, developing a seamless, uniform connection as solid as the pipe itself. This leak-proof joint is crucial in gas and water circulation, where leakages might bring about dangerous scenarios or pricey waste.: HDPE pipes are lighter than typical metal pipelines, making them simpler to deliver and install.

Our basic and quick ordering procedure and reliable logistics ensure you receive your 4-inch HDPE pipeline in the shortest feasible time (hdpe pipe in stock Midland TX). Our after-sales team is offered 24/7 to assist with any concerns you might run into, making sure peace of mind.

PE 80 is for simple industrial applications like gas and water, while PE 100 provides long-lasting toughness and efficiency for tougher uses. For a succinct appearance at applications, below are several of the most usual kinds of HDPE piping and their applications. Piping systems make use of PE 32 or PE 40 for low-pressure applications.

How American Plastics can Save You Time, Stress, and Money.

PE 80 has a material resistant to cracks, so it's ideal in applications vulnerable to cracking, like sewer system and water circulation lines. PE 100 is additionally resistant to splits, and 100 N/mm2 is the minimum required strength. As discussed, categories of HDPE piping include small stress, material, and color coding.

Producers generate pipelines with different pressure grades (PN qualities). This shows the pressure in bars the pipeline can sustain with water at 68 levels Fahrenheit. The stress grades comply with European standards, and they are: PN 2.5 max stress 2.5 bar PN 4max stress 4 bar PN 6max pressure 6 bar PN 10max stress 10 bar PN 16max pressure 16 bar The color codes that show the pressure quality are yellow for PN4, red for PN6, blue for PN10, and environment-friendly for PN16.

The total list of sizes is comprehensive. Nonetheless, pipeline providers supply sizing guides with extra information like wall surface density and mass. Quality control follows ISO criteria regulating the material style and minimum necessary strength (MRS) of pipelines. Generally, high quality assurance tests educate the manufacturers if the HDPE pipelines can provide 50-plus years of service under regular operating problems.

Industries take into consideration small pressure, product, and various other components when identifying which pipes to use - https://zenwriting.net/americanplastics/high-quality-hdpe-pipe-thats-built-to-last. Today, you'll see high-density polyethylene pipes in water supply, gas circulation, agriculture, and much more.

American Plastics - The Facts

Mining business make use of pipelines for slurry transport and dewatering. HDPE piping can safeguard cable televisions in the telecom market. This is helpful for underground cable televisions. The very best component is that services can utilize general PN course pipelines for this application. Industries choose HDPE piping over typical pipes because they use a lot more advantages.

For beginners, HDPE pipes are incredibly long lasting and can last a long period of time with minimal upkeep. They're also resistant to corrosion, chemicals, and UV rays. https://tx-midland.cataloxy.us/firms/american-plastics.com.htm. HDPE click over here now pipelines are also affordable contrasted to other piping products. They're much less prone to damages, which reduces repair expenses! HDPE pipelines are lighter than typical pipelines for far better handling and transportation.

The Best Guide To American Plastics

Whether you're a contractor, designer, or do it yourself enthusiast, this article will certainly give you with the expertise to make informed decisions and achieve ideal results. When it pertains to choosing the ideal HDPE pipeline for your job, recognizing the PSI rating is of utmost importance. The PSI score gauges the stamina and stress capacity of the pipe, indicating how much pressure it can hold up against without failing.The PSI rating of an HDPE pipe establishes its capacity to deal with various stress degrees. Pipelines with greater PSI rankings can hold up against better stress, making them appropriate for applications that involve greater liquid or gas stress. On the various other hand, pipelines with reduced PSI scores are excellent for low-pressure applications.

Report this wiki page